Made Use Of Transformer Oil Recycling: Eco-Friendly Disposal and Reuse Options

Made Use Of Transformer Oil Recycling: Eco-Friendly Disposal and Reuse Options

Blog Article

Why Dielectric Transformer Oil Matters: Trick Functions and Maintenance Tips

The value of dielectric transformer oil expands beyond mere functionality, playing a crucial function in both the insulation and cooling of electric transformers. Its special residential properties, such as high dielectric strength and chemical stability, add to operational efficiency and safety and security. The maintenance of these oils is similarly crucial to protect against problems that might jeopardize transformer efficiency. Comprehending the essential characteristics and finest practices for upkeep is essential for making sure longevity and dependability. As we explore these elements better, the implications for transformer health and wellness and functional effectiveness come to be increasingly evident.

Value of Dielectric Transformer Oil

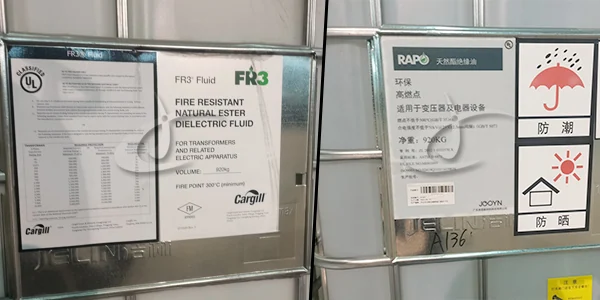

Dielectric transformer oil plays a crucial role in the effective procedure of electric transformers, as it is consistently employed as both an insulator and a coolant. Its shielding properties avoid electric discharges and arcing, which are essential to preserving the honesty of transformer components. By efficiently isolating conductive parts, dielectric oil improves the security and dependability of the transformer, thus prolonging its operational life-span.

Along with its insulating capacities, dielectric transformer oil acts as a coolant, soaking up and dissipating warmth created throughout the electric improvement procedure. This thermal administration is vital to protect against getting too hot, which can cause devices failure and expensive downtime. The oil circulates within the transformer, efficiently moving warmth far from important areas, thus ensuring optimum efficiency.

Additionally, the chemical stability of dielectric oil is important for minimizing the oxidation and destruction that can take place gradually (waste transformer oil). Routine monitoring of its properties, such as dampness material and acidity, is crucial for keeping its effectiveness. Overall, the value of dielectric transformer oil can not be overstated, as it is basic to the risk-free, effective, and lasting operation of electrical transformers

Secret Characteristics of Dielectric Oil

The performance of dielectric transformer oil is mostly determined by its crucial qualities, which include high dielectric stamina, thermal conductivity, and chemical security. High dielectric stamina is crucial as it enables the oil to withstand considerable voltage levels without breaking down, therefore stopping electric arcing and guaranteeing secure operation of the transformer. This particular is vital for preserving the integrity of electrical systems.

Thermal conductivity is one more crucial function of dielectric oil. It promotes efficient heat dissipation from transformer elements, minimizing the danger of getting too hot and prolonging the life expectancy of the tools (electrical insulating oil). Reliable thermal management is important in keeping optimal operating temperatures, which straight affects efficiency

Chemical security is equally essential, as it makes sure that the oil does not weaken or react negatively with materials within the transformer gradually. This security aids keep the oil's insulating homes and stops the development of unsafe sludge or down payments that can harm capability.

Additionally, low viscosity at running temperature levels permits better circulation within the transformer, enhancing both cooling and insulation. With each other, these vital features make certain that dielectric transformer oil performs properly, sustaining the total performance and reliability of electrical systems.

Advantages of Making Use Of Dielectric Oil

Furthermore, dielectric oil functions as a reliable coolant, dissipating heat generated during transformer operation. This temperature policy is necessary for preventing overheating, which can result in devices see here now failing or minimized life-span. The oil's thermal properties add to ideal functional problems, allowing transformers to operate at their ideal.

An additional substantial benefit is the oil's chemical security and resistance to oxidation. These properties reduce the formation of sludge and other destruction byproducts, thereby minimizing maintenance needs and expanding the periods in between oil modifications. Moreover, dielectric oil supplies exceptional wetness absorption capacities, which shield the transformer from the destructive impacts of water access.

Upkeep Ideal Practices

Additionally, maintaining the transformer's temperature within specified limits is important. Raised temperature levels can increase oil degradation, adversely affecting its dielectric residential or commercial properties. Executing a temperature monitoring system can aid in maintaining optimal problems.

In addition, ensuring correct air flow and air conditioning of the transformer system lessens the danger of overheating. It is Look At This also important to maintain the transformer devoid of particles and pollutants that may compromise its performance.

Performing periodic aesthetic assessments for leakages, rust, or signs of endure gaskets and seals is another ideal method. Any problems must be dealt with promptly to avoid oil contamination and preserve system honesty.

Finally, establishing an upkeep schedule that consists of oil replacement or therapy can enhance the life expectancy of dielectric oil, ensuring it continues to perform successfully. By adopting these upkeep ideal methods, drivers can optimize transformer efficiency and minimize unintended downtime.

Common Problems and Solutions

Transformers making use of dielectric oil can experience numerous common problems that might impact their efficiency and reliability. One popular concern is the degradation of the oil because of thermal stress and anxiety, which can result in reduced dielectric toughness and enhanced danger of arcing. Normal monitoring of the oil's temperature and applying cooling solutions can reduce this issue.

An additional concern is moisture ingress, which can jeopardize the shielding residential or commercial properties of the oil. This can be attended to through normal screening for water content and employing desiccants or vacuum dehydration processes to eliminate wetness.

In addition, the development of sludge as a result of oxidation can obstruct normal operation. This can be fixed by regular oil purification and substitute when essential, making certain optimal fluid cleanliness.

Final Thought

To conclude, dielectric transformer oil plays a crucial role in making sure the reliable operation and safety and security of electrical transformers. Its essential features, including high dielectric stamina and chemical security, contribute to ideal efficiency while minimizing maintenance demands. Sticking to best maintenance techniques, such as normal monitoring of wetness and level of acidity, is essential for stopping usual concerns and enhancing the operational life expectancy of transformers. The value of dielectric transformer oil can not be overemphasized in the realm of electrical facilities dependability.

The importance of dielectric transformer oil prolongs beyond simple performance, playing an essential function in both the insulation and air conditioning of electric transformers.Dielectric transformer oil plays a vital duty in the reliable procedure of electric transformers, as it is constantly utilized as both a coolant and an insulator. Generally, the value of dielectric transformer oil can not be overstated, as it is essential to the safe, dig this efficient, and long-term procedure of electric transformers.

The performance of dielectric transformer oil is mainly figured out by its crucial qualities, which include high dielectric strength, thermal conductivity, and chemical security.In verdict, dielectric transformer oil plays a crucial function in ensuring the efficient procedure and security of electrical transformers.

Report this page